Engineered Elastomers

Gulf works with comprehensive engineered elastomers including LSR and chlorine resistant elastomers. These materials have unique properties and characteristics that solve complex challenges and meet the specifications for various industry standards and applications.

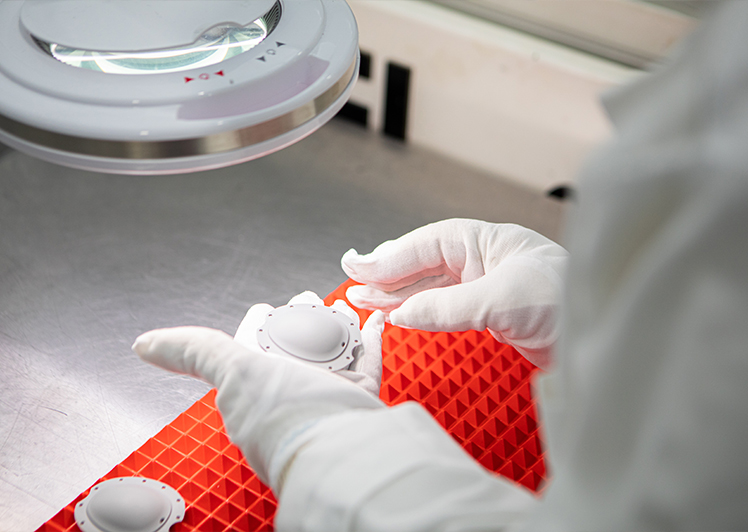

Liquid Silicone Rubber Manufacturer (LSR)

Liquid silicone rubber is a silicone based thermoset polymer that is supplied as a liquid and cured with heat to form a permanent shape. Application is suitable for a wide range of operating temperatures and often used where traditional rubber materials are not suitable. It is easy to work with, great for bonding, resistant to a wide range of chemicals, and carries a low material weight, making it ideal for use in a variety of applications.

High Consistency Rubber (HCR)

Gulf works with a broad spectrum of polymers that can be engineered to have a wide range of properties including flexibility, durability, less weight, and resistance to heat and chemicals. They are cost effective and can be easily molded, extruded, and formed into a variety of shapes. This versatility enables our team to help you select the best material for your custom product.

Chlorine Resistant Elastomer Manufacturer

A chlorine resistant compound is a substance that maintains its structural integrity when exposed to chlorine. As a chlorine resistant elastomer manufacturer, we often use this material to design and develop water pipes and water treatment systems due to its ability to kill bacteria and other microorganisms. In healthcare, where sterilization is crucial, chlorine-based disinfectants are commonly used. This means that medical device components need to be designed and developed to withstand exposure to disinfectants without degrading or losing their functionality. In both use cases, and many others, creating a product from chlorine resistant compounds prolongs the lifespan of the materials they are used in.

Quality Assurance

Gulf’s team of engineers ensure all factories around the world meet quality standards required for ISO 9001 and ISO 13485 certifications. All products go through rigorous analysis and testing on a range of metrics, including tensile and tear strength, stress relaxation, and compound rheology. Our stringent process controls use tools such as Poka-Yoke / Error-Proofing, Statistical Process Control (SPC), Process Failure Mode Effects Analysis (PFMEA) and automated inspection tools.

Other analytical tools include Design of Experiments (DoE), Finite Element Analysis (FEA), Failure Modes and Effects Analysis (FMEA), Gauge R&R and 8D Problem Solving.

Custom Design Capability

Using DFMA (design for manufacture and assembly), we can help duplicate parts, improve existing parts, or develop new ones. In partnership with you, products are developed, tested, and delivered to streamline production and simplify your supply chain, often resulting in lower cost products and quicker delivery time.

Book a Consultation

Schedule a consultation and share your product challenges and objectives. Our technical team will help you understand and discuss our design and development process to deliver in full, on time, and within specification.