World-Class Manufacturing Leader

in Sealing Solutions, Devices, and Assemblies

What We Do

An initial consultation begins the process to understand your product, your needs, and industry requirements. Our team are the leading experts in material science, engineering and design, compounding and mixing, rapid prototyping, molding and overmolding, assemblies and subassemblies. Your product will go through rigorous performance testing in our in-house quality labs, and we will package and distribute your product anywhere in the world.

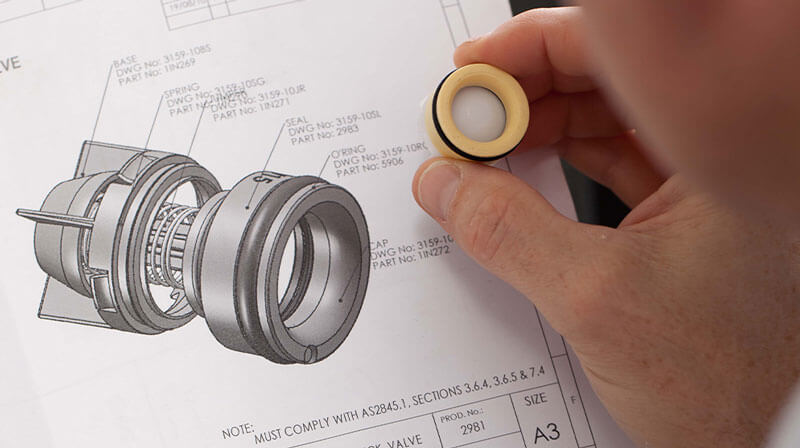

Custom Engineered Solutions

In partnership with you, our technical team will develop custom engineered solutions tailored to your product’s complex challenges. If you are developing a new product, or modifying an existing one, tough industry specifications and tight timelines require our team’s specific engineering expertise from product conception to delivery. Our materials, processes and certified quality ensure an undeniable advantage as you bring your product to market.

Whether it’s pressure switch diaphragms crucial for industrial processes, medical device components vital for healthcare innovation, TYTON™ gaskets for pipe sealing, water irrigation controls for farming, or chlorine-resistant compounds tailored for specific applications, our commitment to excellence remains unwavering. Choose our products for unmatched quality, durability, and precision in meeting the demands of your industry.

About Gulf

We are global design and manufacturing leaders of precision-engineered, rubber and plastic products and components for OEM customers. With locations in the US, Europe, Australia, New Zealand, and Vietnam – we work around the clock to produce quality, durable, high-end rubber and plastic components for a range of verticals.

Partner Reviews

Partner Reviews

Quality Assurance

Gulf’s team of engineers ensure all factories around the world meet quality standards required for ISO 9001 and ISO 13485 certifications. All products go through rigorous analysis and testing on a range of metrics, including tensile and tear strength, stress relaxation, and compound rheology. Our stringent process controls use tools such as Poka-Yoke / Error-Proofing, Statistical Process Control (SPC), Process Failure Mode Effects Analysis (PFMEA) and automated inspection tools.

Other analytical tools include Design of Experiments (DoE), Finite Element Analysis (FEA), Failure Modes and Effects Analysis (FMEA), Gauge R&R and 8D Problem Solving.

Custom Design Capability

Using DFMA (design for manufacture and assembly), we can help duplicate parts, improve existing parts, or develop new ones. In partnership with you, products are developed, tested, and delivered to streamline production and simplify your supply chain, often resulting in lower cost products and quicker delivery time.

Book a Consultation

Schedule a consultation and share your product challenges and objectives. Our technical team will help you understand and discuss our design and development process to deliver in full, on time, and within specification.