Engineered Materials

Gulf uses materials that allow for the design and production of products with precise characteristics that meet the needs of specific applications.

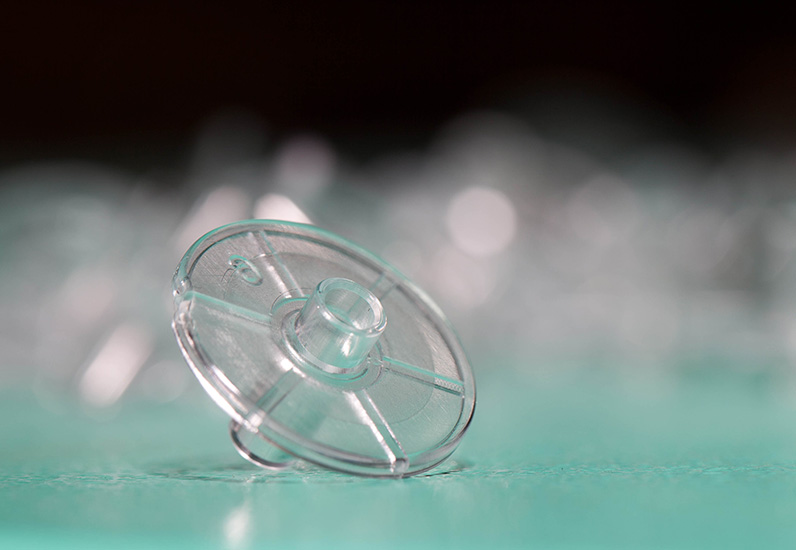

Thermoplastics

Thermoplastics are a type of polymer used in a variety of applications due to their versatility, cost-effectiveness, and availability. A defining characteristic of a thermoplastic is its ability to be melted and molded at sufficient heat, and reshaped multiple times without degrading. The overmolding capability of thermoplastics can also reduce the complexity of your assembly or sub-assembly, and they are often utilized to convert two parts into one.

onto these plastic resins:

POM – Polyoxymethylene

PPA – Polypthalamide

PPO – Polyphenylene Oxide

PA66 – Nylon 66

PEI – Polyether Imide

PPS – Polyphenylene sulphide

PSU – Polysulphone

Thermoplastic Elastomer

Thermoplastic elastomers are known for their flexibility, high elasticity, and excellent shock absorption properties. They are a lower cost solution that exhibit the elastic properties of a rubber and the processing characteristics of a thermoplastic. This contributes to their durability, UV, and tear and impact resistance. Each TPE is used for specific applications based on performance characteristics. TPEs can be found in a variety of products including automotive parts, toys, and medical devices.

Quality Assurance

Gulf’s team of engineers ensure all factories around the world meet quality standards required for ISO 9001 and ISO 13485 certifications. All products go through rigorous analysis and testing on a range of metrics, including tensile and tear strength, stress relaxation, and compound rheology. Our stringent process controls use tools such as Poka-Yoke / Error-Proofing, Statistical Process Control (SPC), Process Failure Mode Effects Analysis (PFMEA) and automated inspection tools.

Other analytical tools include Design of Experiments (DoE), Finite Element Analysis (FEA), Failure Modes and Effects Analysis (FMEA), Gauge R&R and 8D Problem Solving.

Custom Design Capability

Using DFMA (design for manufacture and assembly), we can help duplicate parts, improve existing parts, or develop new ones. In partnership with you, products are developed, tested, and delivered to streamline production and simplify your supply chain, often resulting in lower cost products and quicker delivery time.

Book a Consultation

Schedule a consultation and share your product challenges and objectives. Our technical team will help you understand and discuss our design and development process to deliver in full, on time, and within specification.