Why the Right Convoluted Diaphragm Design Can Make or Break Your Product

Convoluted diaphragms are a great example of small components carrying the biggest weight. They are flexible, resilient, and seemingly simple, however, they can either elevate your product’s performance or quietly sabotage it. This is why having the right convoluted diaphragm for your product is one of the smartest investments you can make in your product’s overall success.

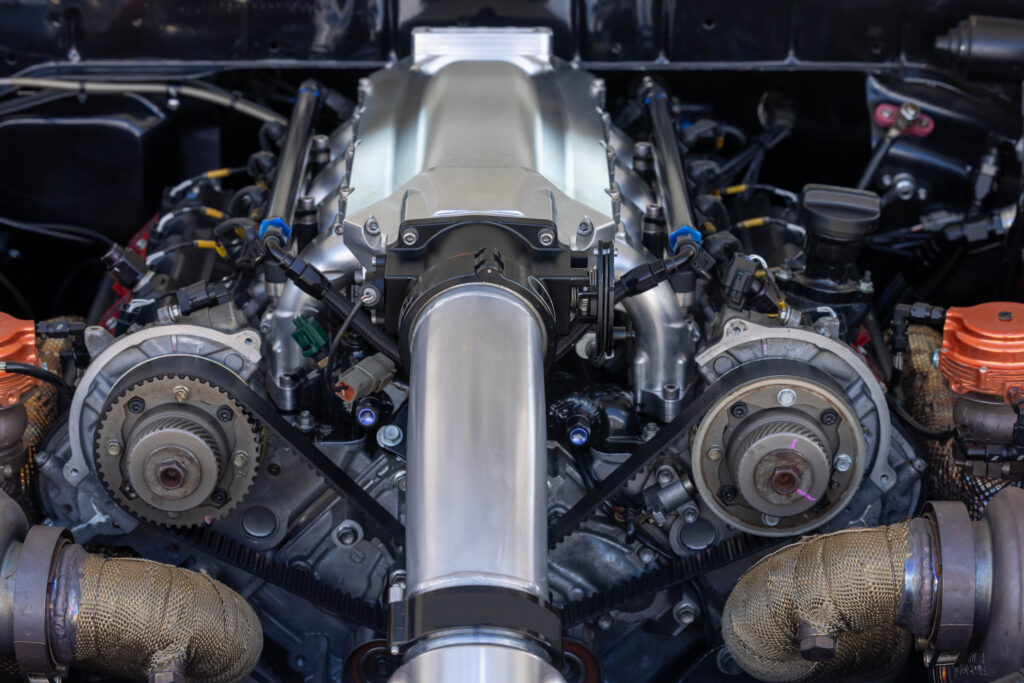

As a custom engineered rubber and plastic manufacturer, we’ve seen it all. From automotive assemblies and medical devices, to industrial systems and irrigation controls. And in our experience, the products that perform as they should, and those that are plagued with issues, boil successes and failures down to the diaphragm.

The Power of the Right and the Risk of the wrong Diaphragm Design

While the job of a diaphragm may seem straightforward, its seemingly simple function is responsible for a lot.

The right diaphragm design:

- Keeps fluids or gases moving as they’re intended

- Maintains the integrity of a seal even in extreme conditions

- Absorbs movement and pressure fluctuations without failure

- Extends the lifespan of the entire system

The wrong diaphragm design:

- Can wear or crack prematurely

- Be chemically incompatible

- Reduces system performance

- Causes costly repairs, warranty claims

- Results in downtime

The Importance of a Custom Designed Convoluted Design

Convoluted diaphragms are designed with performance in mind. Their rippled, flexible shape increases range of motion and fatigue resistance, making them ideal for repetitive movement or long-term pressure.

A custom engineered convoluted diaphragm from Gulf is precision-molded to fit your unique products and industry specifications. From medical devices, heavy-duty industrial systems, to water irrigation controls, we design convoluted diaphragms with your product’s lifecycle in mind.

Why Design Collaboration Matters for Convoluted Diaphragms

While specs may have come first in your previous component manufacturing experience, our process starts with a conversation and collaboration. We work with your project team to understand how the diaphragm in your product needs to function within its broader system. This ensures integration is seamless, longer performance, and fewer surprises.

Offering a range of elastomers and design flexibility, we aim to understand your product environment and the various nuances that may affect its performance over time. We’ll help you to choose the best fit materials and run rigorous testing to get your diaphragm ready for product integration.

Start Your Next Convoluted Diaphragm Project With Gulf

When poorly designed, these components will not do their jobs, and downtime, repairs, and customer dissatisfaction is something we all want to avoid. If you need to manufacture a new convoluted diaphragm, or are seeing inconsistent performance in your current product, Gulf can help.

Let’s talk about how a custom convoluted diaphragm could improve reliability, reduce cost, and enhance your product’s performance.