Valved Introducer Manufacturer Reviews Benefits & Uses for Medical Industries

In the medical device industry, precision and reliability are crucial. One of the widely used medical devices that relies on these qualities is the valved introducer. Below, our engineering experts explain the valved introducer’s material composition, uses in the medical field, benefits of quality manufacturing, different types of valved introducers, and why partnering with a trusted manufacturer like Gulf Engineered Rubber and Plastics Solutions can make a significant difference.

What is a Valved Introducer and Why is Quality Manufacturing Important?

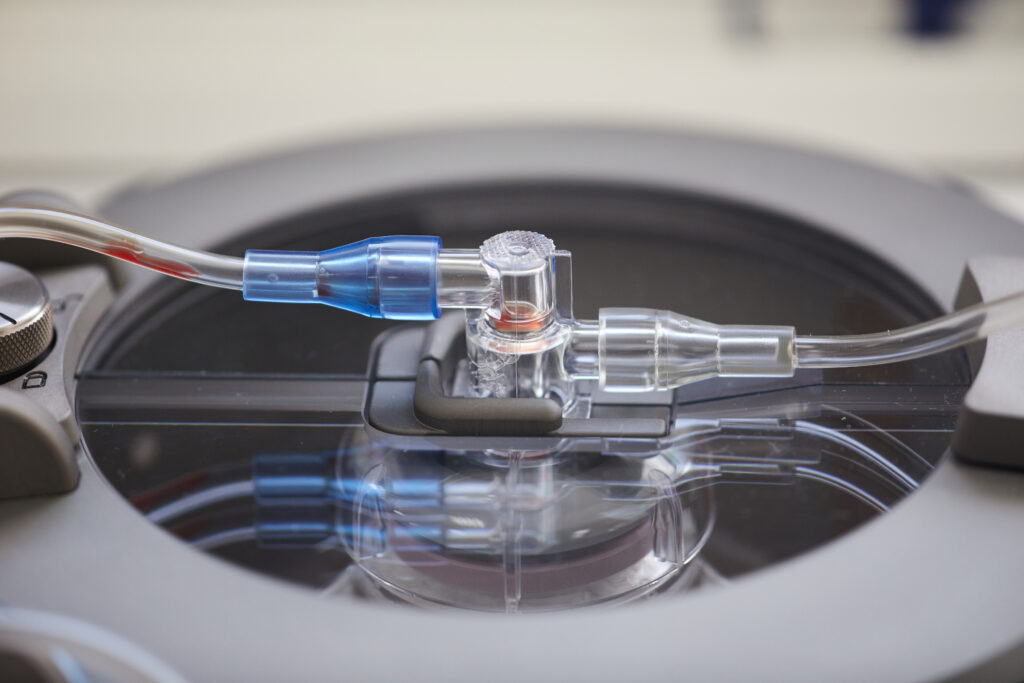

A valved introducer is a medical device used to insert catheters or other instruments into the body while maintaining hemostasis (preventing blood loss). It typically consists of a sheath with an integrated valve mechanism that allows for smooth entry and removal of instruments without compromising the sterility of the procedure. The quality of manufacturing is important because these devices must operate flawlessly for patient safety and procedural efficiency.

Material Makeup of Valved Introducers

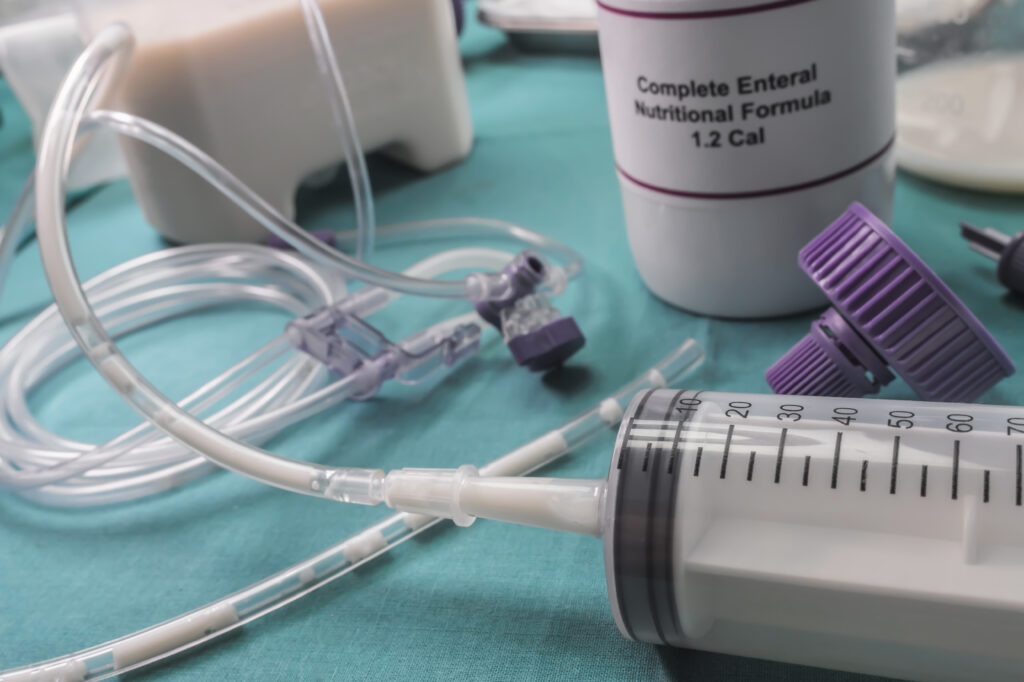

The materials used in the manufacturing of valved introducers are carefully selected for their biocompatibility, durability, and flexibility. Common materials include:

- Medical-grade polymers: Such as polyurethane or polyethylene, which provide flexibility and strength.

- Silicone: Used for its excellent biocompatibility and resistance to various fluids.

- Synthetic Polyisoprene: This is a latex-free alternative to Natural Rubber that has high elongation and resilience that facilitates sealing against a wide range of diameters from small guide wires to larger catheters, cameras, balloons, stents, and other devices.

- Stainless steel: Often used in the construction of the introducer’s needle for its strength and precision.

At Gulf Rubber US, we ensure that all materials meet stringent medical standards and are thoroughly tested for performance and safety.

Uses for Valved Introducers

As reviewed above, valved introducers are commonly used in a handful of medical procedures. More specifically, they’re used in cardiovascular interventions for introducing catheters during angioplasty or stent placement. They’re also used in electrophysiology studies to guide diagnostic or therapeutic catheters into the heart. Interventional radiology uses them for the placement of central venous catheters or other vascular access devices. Even neurosurgeons use valve introducers to assist in the precise placement of neurostimulators or other delicate instruments.

Benefits of Quality-Manufactured Valved Introducers

High-quality valved introducers offer several benefits. One of the most important benefits being enhanced patient safety. They ensure safety by reducing the risk of infection and complications in certain procedures. Additionally, valved introducers improve procedural efficiency by allowing for smoother and quicker instrument exchanges. They also offer greater reliability by providing consistent performance under various conditions. Valved introducers can even reduce healthcare costs by minimizing the need for replacements or addressing complications.

Different Types of Valved Introducers

Valved introducers can be altered to meet specific clinical needs. Therefore, there are a few different types that can be produced. These include:

- Standard valved introducers: Used for general catheter insertion.

- Micro-introducers: Designed for small vessel access.

- Dual-valved introducers: Providing additional security and versatility during complex procedures.

Work With Our Reliable Engineers to Produce Valved Introducers

When using valved introducers, one is typically performing a very delicate procedure. Therefore, it is critical that they are manufactured properly to perform flawlessly when it matters most. We pride ourselves on delivering top-of-the-line engineered rubber and plastic solutions, including high-quality valved introducers.

Contact our team today to learn more about our custom solutions to see how we can help you fulfill any needs for medical device manufacturing. Together, we can make a difference in patient care and procedural success.