Understanding Convoluted Diaphragms vs Non-Convoluted: Benefits and Uses

Each type of diaphragm has its own benefits across various industries. This blog post will review the differences between convoluted diaphragms and non-convoluted diaphragms. As a trusted diaphragm manufacturer, choosing between one or the other is a critical decision as each type has its own uses and benefits. This in depth overview of both types of diaphragm should help you get a little closer to which may be best suited for your project.

What is a Diaphragm?

A diaphragm is a flexible membrane that reacts to pressure and the force transfers and triggers another mechanical action. We typically manufacture diaphragms to be used in pumps, valves, actuators, and many other industrial applications where regulation and fluid control is paramount.

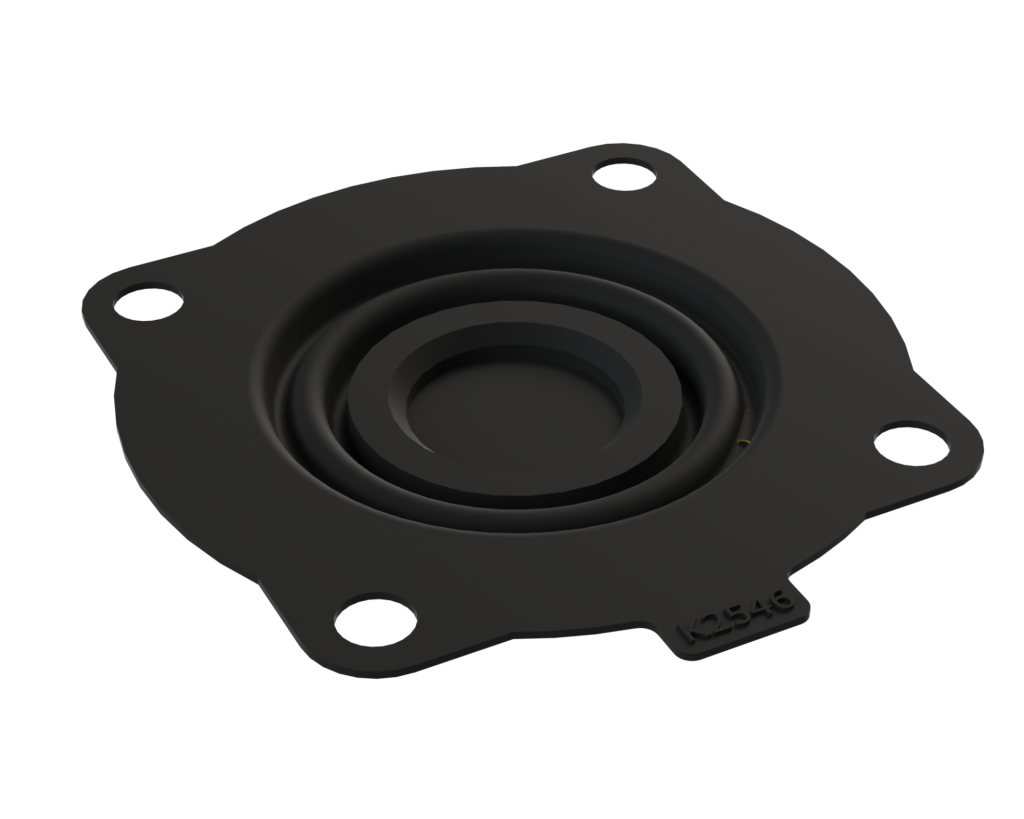

What is a Convoluted Diaphragm?

Convoluted diaphragms are known for their wavy, accordion-like design. This shape and structure enables flexibility and increased range of motion. The greatest benefit of a convoluted diaphragm is the enhanced flexibility that allows them to stretch and compress making them ideal for applications with a lot of movement. This flexibility also means less stress on the material, promising a longer life span in most applications and less frequent replacements.

Manufacturing convoluted diaphragms for many projects, we also find they have greater sensitivity to pressure changes, which makes them a good fit for instruments that require precision. In addition, the convoluted diaphragm allows for better sealing in certain applications enhancing the overall performance of the equipment.

What Applications Use Convoluted Diaphragms?

Pumps and Compressors: These applications both require a diaphragm that can withstand movement and pressure fluctuations, making the convoluted diaphragm the perfect option.

Actuators: Their flexibility and responsiveness are crucial for precise control in pneumatic and hydraulic actuators.

Medical Device Components: Convoluted diaphragms are used in various medical device components where precision and reliability are top priority.

What is a Non-Convoluted Diaphragm?

Non-convoluted diaphragms have a simpler, flat structure without any wavy design like the convoluted diaphragm. The benefits of non-convoluted diaphragms are their simplicity and cost effectiveness, durability, consistency, and they are easy to maintain.

Since the design of the non-convoluted diaphragm is flat, it makes them easier and cheaper to manufacture. As a leading diaphragm manufacturer, we suggest selecting the diaphragm that will be most reliable and fitting for your product and application and not solely rely on simplicity and reduced cost.

Even though the non-convoluted diaphragm is less flexible than the convoluted diaphragm, it is made from robust materials that can withstand high pressures which are important for applications with harsh operating conditions. In addition, since the design is flat, performance reliability is a great benefit. This is great for applications that operate with consistent pressure. The same goes for maintenance. The simpler the design, the easier to maintain.

What Applications Use Non-Convoluted Diaphragms?

Industrial Valves: Non-convoluted diaphragms work very well for industrial applications, and valves specifically, because of their ability to provide consistent performance in high pressure conditions.

Pressure Regulators: Given it’s crucial to maintain stable pressure in regulators, the non-convoluted flat design and consistent performance in harsh conditions works well for this application.

Instrumentation: Gauges and other instruments also prefer to use the non-convoluted diaphragms as they require precision measurement.

How Do You Choose The Right Diaphragm For Your Application?

When you are working with a manufacturer to decide between a convoluted and a non-convoluted diaphragm, the factors we recommend you consider are range of motion, pressure requirements, precision needs, and cost considerations.

Range of Motion: If your application requires significant movement or flexibility, a convoluted diaphragm is likely the better choice for you.

Pressure Requirements: For high-pressure environments, non-convoluted diaphragms made from robust materials may be more suitable.

Precision Needs: Convoluted diaphragms offer greater sensitivity, making them ideal for precision instruments.

Cost Considerations: Non-convoluted diaphragms are generally more cost-effective due to their simpler design and manufacturing process. We always want to put an asterisk on this one, as it’s important to consider cost along with functionality when selecting a diaphragm, not only cost considerations.

Contact Gulf Engineered Rubber and Plastics Solutions (Gulf) For Questions About All Diaphragm Projects.

Both convoluted and non-convoluted diaphragms have their unique advantages and ideal applications. Understanding the differences between the two can help you make an informed decision that enhances the performance and longevity of your equipment. Whether you need the flexibility of a convoluted diaphragm or the robustness of a non-convoluted one, selecting the right diaphragm is crucial for achieving optimal results and our expert team at Gulf can help as you begin your project.