Top 10 Questions We Get as a Chlorine Resistant Elastomer Manufacturer

As a chlorine resistant elastomer manufacturer, our team of engineers receives questions every day about material selection. We thought it would make sense to gather the most frequently asked questions about popular materials and put them in one place. In this blog post, let’s review the top 10 questions we get asked as a chlorine resistant elastomer manufacturer and provide clarity and insights into this wildly used elastomer and its diverse uses.

1. What are chlorine resistant elastomers?

Chlorine resistant elastomers are materials that are designed to withstand exposure to chlorine without degrading or deteriorating over time. They play a critical role in sealing and gasketing applications where exposure to chlorine is prevalent, in particular potable water applications. Similar products are also utilized for applications that require resistance to other harsh chemicals, UV radiation, and harsh environmental conditions.

2. What types of elastomers are chlorine resistant?

The following is a list of widely used chlorine resistant elastomers.

Ethylene propylene diene (EPDM) rubber

Silicone (VMQ) Rubber

Fluorocarbon (FKM) Rubber

Nitrile Butadiene (NBR) Rubber

Styrene Butadiene (SBR) Rubber

3. Where are chlorine resistant elastomers used?

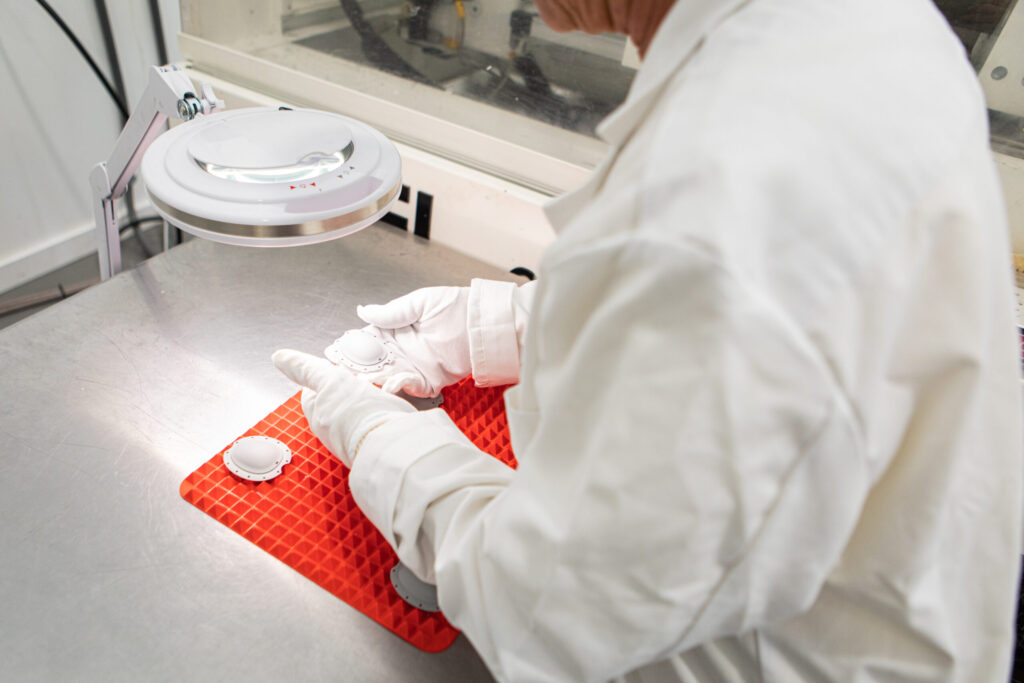

As a chlorine resistant elastomer manufacturer, we understand the complexities of this material best applications for its use. The most common industries where we see chlorine resistant elastomers used are water treatment facilities, swimming pools, chemical processing, automatic manufacturing, and outdoor equipment as well as household plumbing and appliances. We use this unique material in seals, gaskets, O-rings, check valves, umbrella valves, duckbill valves, and hoses.

4. What are the benefits of chlorine resistant elastomers?

The most beneficial qualities of chlorine resistant elastomers are durability, longevity, chemical resistance, UV resistance, and flexibility. Because of these unique qualities, we are able to provide our customers with component solutions in challenging environments, and reduce maintenance and downtime costs.

5. How do chlorine resistant elastomers compare to standard elastomers?

We often have to compare materials as a chlorine resistant elastomer manufacturer. The most noteworthy differences between chlorine resistant elastomers and standard elastomers is their durability and flexibility. The materials are able to maintain their properties and sealing capabilities when in the presence of chlorine. In addition, these elastomers are flexible. This allows them to keep a good seal, low compression set, and high resilience.

6. Can chlorine resistant elastomers be customized for specific applications?

Yes, chlorine-resistant elastomers can be customized to meet the specific requirements of different applications and industries. As the chlorine resistant manufacturer, we can adjust material formulations, hardness levels, and physical properties to optimize performance in various environments, ensuring compatibility and longevity in unique environments.

7. What factors should be considered when selecting chlorine resistant elastomers?

It’s important to consider chemical compatibility, temperature range, pressure ratings, mechanical properties, and regulatory compliance when selecting a chlorine resistant elastomer for your project. As your chlorine resistant elastomer manufacturer, we will work with you to help understand application requirements and determine which material is best for your specific needs.

8. Are chlorine resistant elastomers environmentally friendly?

As a global manufacturer, it’s important to us to be as eco-friendly as possible and lessen our environmental footprint where we can. Many factors come into play when considering sustainability, and we take the environment into consideration in each part of the process. When it comes to the environment we consider where and how we are sourcing materials, the actual manufacturing process, and what we do with material waste.

9. What happens if chlorine resistant elastomers are not maintained?

It is paramount that chlorine resistant elastomers are maintained according to manufacturer guidelines. If they are not checked periodically and replaced as needed, you will see degradation of material properties, component performance failure, increased maintenance costs, and risk of contamination. That said, always follow best practices for maintenance.

10. What is the typical shelf life for chlorine resistant elastomers?

These elastomers average a shelf life of several years, however, this will vary greatly depending on a number of factors including material composition, storage conditions, and environmental exposure. They need to be stored properly in a cool, dry, and dark environment away from direct sunlight, heat sources, and moisture. Regular material inspections and maintenance can also lengthen the shelf life of this material. If materials are not being used, it’s important to keep chlorine resistant elastomers in their original packaging.

Begin Your Next Project With a Chlorine Resistant Elastomer Manufacturer

If your questions were not answered here, contact us to speak to one of our expert engineers for support and guidance. A consultation will help us understand your product as a whole, its parts, and assembly. We listen to your pain points and work with our design team to create a unique solution for your product and industry.