Stop the Leaks Before They Start: How the Right Pipe Gasket and Manufacturer Protects Your System

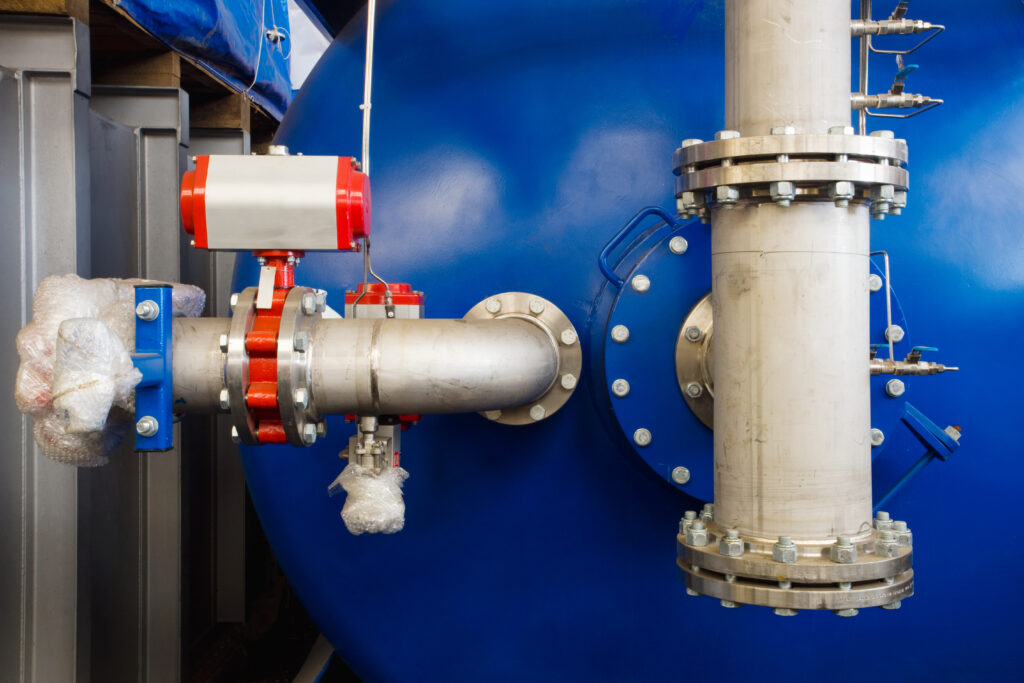

Piping systems are complex, and we all know that failures aren’t easy to detect. They typically don’t start with a burst, but a small drip. This is exactly why pipe gaskets play a silent, but vital, role in keeping systems operational and efficient across various industries. As a pipe gasket manufacturer, we’ve worked across industries such as water treatment, energy, manufacturing, and infrastructure. While they all come with their own nuances, there is one thing that’s consistent – the essential role of the pipe gasket.

In this blog, we’ll explain what a pipe gasket is, its applications and benefits, and the value of choosing the right pipe gasket manufacturer.

What Is a Pipe Gasket?

A pipe gasket is a mechanical seal that fills the space between two mating pipe surfaces to prevent leakage under compression. They can be made from elastomers like rubber, silicone, or nitrile. They are purposely designed to withstand pressure, changes in temperature, and the movement of fluid in a range of operating conditions.

In applications where tight, leak-proof conditions are a must, pipe gaskets are essential. They adapt and accommodate for irregularities in surfaces, absorb vibrations, keep a reliable seal over time, and more.

Common Applications for Pipe Gaskets

Pipe gaskets are used in a variety of industries and system types, many of which you’ll never see. The following applications demand reliable sealing performance, and that starts with the right pipe gasket and the right pipe gasket manufacturer.

Municipal Water & Wastewater: Pipe gaskets prevent leaks and contamination in underground water mains, pump stations, and treatment plants.

Oil & Gas: It is critical to seal high-pressure, high-temperature pipelines where safety measures and environmental compliance need to be followed.

Industrial Manufacturing: Systems that transport steam, chemicals, and other process fluids across plants and facilities often use pipe gaskets for their numbered sealing benefits.

Construction & Infrastructure: Pipe gaskets provide airtight seals in stormwater systems, building piping, and complex HVAC infrastructure.

Food & Beverage: Pipe gaskets provide sanitary sealing solutions for processing lines that require compliance with FDA or NSF standards.

The Benefits of the Right Pipe Gasket

A properly engineered pipe gasket will do much more than seal a joint, it will optimize your entire system. Here’s how:

Leak Prevention: A top quality pipe gasket will help you select the right material composition to prevent leaks under your system’s pressure. This will also reduce the risk of environmental contamination and equipment damage.

System lifecycle: Using the right pipe gasket releases the stress on your other system components which will extend the life of both the gasket and the piping itself.

Safety & Compliance: Quality pipe gaskets will meet the regulatory requirements of your industry. This will reduce liability and improve the safety of your workplace. This is especially true when working with systems that carry hazardous or high-pressure materials.

Cost Efficient: The proper seal will prevent costly repairs, downtime, and emergency maintenance. Over time, this will mean a higher return on investment.

Preventative sealing minimizes costly repairs, downtime, and emergency maintenance, providing a higher return on investment over time.

Performance Stability: Pip gaskets engineered and manufactured to the right specs ensure consistent flow rates, pressure levels, and overall efficiency across all conditions and seasons.

Why the Right Pipe Gasket Manufacturer Matters

If a pipe gasket is poorly manufactured, even the best designs will fail. This is why selecting an experienced, reputable pipe gasket manufacturer is a critical first step in the process.

Pipe gasket manufacturers will:

Have material expertise. They’ll understand where EPDM and nitrile work best, or when custom elastomer design is needed for high heat or chemical exposure.

Understand industry compliance requirements. They’ll adhere to ASTM, AWWA, WRAS, or NSF standards to make sure your systems are safe, legal, and ready for inspection.

Provide custom engineering support. When cookie-cutter doesn’t cut it, the right pipe gasket manufacturer will work with you to create a custom profile, develop a prototype, providing tooling support to get your seal exactly how you need it.

Deliver consistent quality control. In sealing, precision and repeatability matter. Top pipe gasket manufacturers will implement rigorous QA/QC processes and have certifications like ISO 9001 to ensure consistent, reliable product performance.

Deliver quick turnaround and support. Delays cost you money. It’s best to select a pipe gasket manufacturer that’s quick to respond and deliver on technical support needs when timelines are tight.

Why Choose Gulf as Your Pipe Gasket Manufacturer?

At Gulf, we’ve spent decades helping companies prevent problems before they start. Our precision-engineered pipe gaskets are designed and manufactured with performance, compliance, and longevity in mind. Whether you’re replacing legacy systems or designing something entirely new, we work with you to build sealing solutions that last.

Looking for a pipe gasket manufacturer you can count on? Start your next project today!