Chlorine Resistant Elastomers Manufacturer Shares The Benefits and Challenges of the Compound

Chlorine Resistant Elastomers Manufacturer Shares The Benefits and Challenges of the Compound

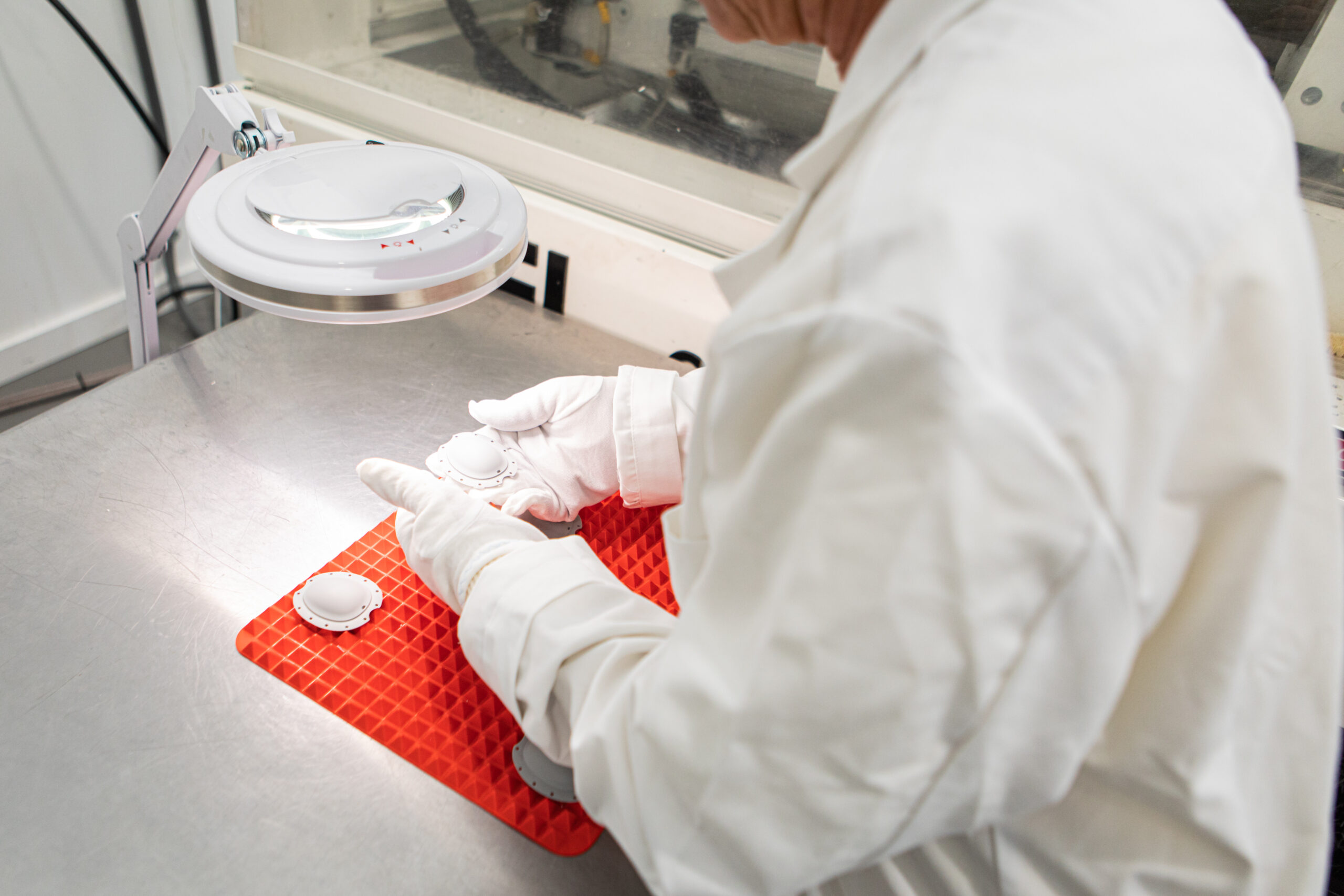

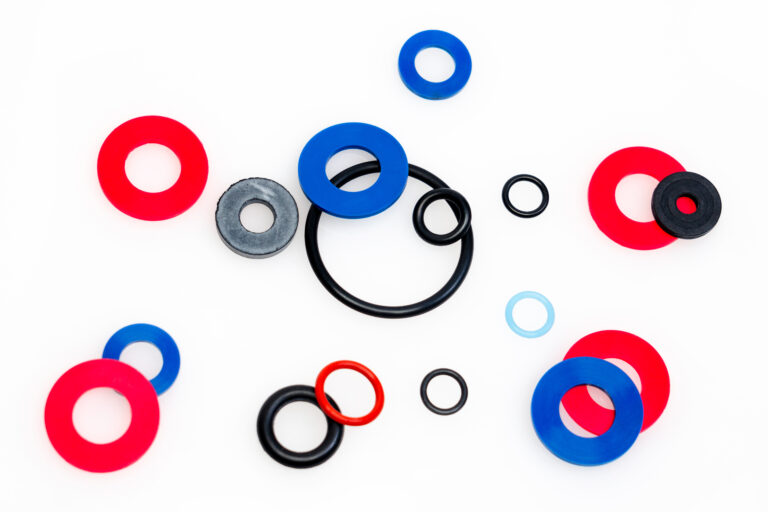

As a chlorine resistance elastomer manufacturer, we understand chlorine and chloramine are disinfectants used to sanitize water; however, these chemicals, in addition to killing disease-causing germs, can also fracture the surface of elastomer products such as seals, O-rings, check valves, and diaphragms depending on the type of polymer and overall formulation of the compound. Eventually, chlorine will degrade many types of elastomers completely. Some elastomers are naturally chlorine resistant, while others will degrade very quickly. This is why material selection is so critical for these applications.

There are many benefits to using chlorine resistant elastomers when manufacturing products for water treatment facilities, healthcare and sanitation industries, industrial processes, and any settings where disinfecting is required.

We’ll also dive into a few of the chlorine resistant elastomers that Gulf US Engineered Rubber and Plastics Solutions uses to manufacture the highest-quality products on the market.

Benefits of Chlorine Resistant Elastomers

There are three main benefits to your product when designing and manufacturing with chlorine resistant elastomers: extended lifespan, sustainable performance, and enhanced safety.

There are three main benefits to your product when designing and manufacturing with chlorine resistant elastomers: extended lifespan, sustainable performance, and enhanced safety.

Extended Lifespan: Chlorine can have various detrimental effects on a product that is not made of a chlorine resistant elastomer. Depending on the specific material and the concentration of chlorine it’s exposed to, chlorine can cause swelling, discoloration and/or degradation of elastomers. If your product application is in a chlorine environment and is designed with a chlorine resistant elastomer, you will reap the benefits of having a prolonged lifespan which results in reduced maintenance costs and minimum downtime.

Sustained Performance: One of the most important quality attributes when manufacturing a rubber product, system, or industry application, is consistent high-level performance. Whether it’s a seal in a water treatment plant, faucet, piping in a swimming pool, or components in industrial machinery, reliability is paramount.

Chlorine resistant elastomers play a pivotal role in ensuring that your product not only performs efficiently but is also durable and reliable, maintaining its integrity over time, even in harsh conditions. This resilience not only enhances operational efficiency but also instills confidence in the lifespan of your products, ultimately bolstering customer satisfaction, trust, and loyalty.

Enhanced Safety: One of the key safety benefits of developing a product with a chlorine resistant elastomer is the prevention of leaks. Creating a seal, for example, from a chlorine resistant elastomer can avoid degradation and prevent inevitable leaks causing a snowball effect of safety and cost issues.

Reduced costs: If you are designing and manufacturing a product that will have consistent exposure to chlorine, it’s important to understand chlorine resistance elastomers are very important to your bottom line. If your product is prone to degradation, leaking, not working efficiently, or losing durability when exposed to chlorine, if you do not design with a chlorine resistant elastomer, you will incur product replacement and warranty claims.

Challenges When Using Chlorine Resistant Elastomers

Manufacturing a product with chlorine resistant ela

stomers doesn’t come without challenges, which is why designing and developing your product with the right partner is one of the key elements to the development process. Below are some of the challenges you may face, and how Gulf finds solutions.

Material Selection: In any product development process, material selection is important and selecting the right chlorine resistant elastomer is critical to your success.

This is why Gulf’s technical team is well versed in the properties of each chlorine resistant elastomer to work with you to select the material that is going to be best suited for your product’s specifications.

Other Chemical Resistance: Oftentimes when an environment is high in chlorine, it can be high in other chemicals. Ensure that when you are selecting the chlorine resistant elastomer for your product, you are also taking into consideration other chemicals that may be present.

For this reason, Gulf starts the product development process with a consultation to understand all use case scenarios and environments for your application.

Compliance Challenges: In the world of manufacturing and chlorine resistant elastomers, quality assurance and compliance are a must for all products to successfully go to market. Each industry and product will have their own set of standards and compliance requirements that must be understood and met at each stage of the product development process.

Gulf understands how important compliance is, which is why the design and manufacturing process begins with a consultation. Gulf works to understand your product as a whole, considering its parts and their assembly to ensure each part of the process is compliant.

Chlorine Resistant Elastomers Commonly Used by Gulf

Chlorine resistant elastomers withstand the corrosive effects of chlorine, but not all are suited for every application. Here are a few chlorine resistant elastomers that Gulf uses and which application they are suited best for.

EPDM

- Material: Ethylene Propylene Diene Elastomer

- Applications: potable water seals, gaskets, diaphragms, o-rings and check valves

FKM (Viton)

- Material: Flouroelastomer

- Applications: Seals, gaskets, o-rings, other industrial applications

VMQ

- Material: Silicone Elastomer

- Applications: Seals, gaskets, o-rings, other industrial applications

Start Your Next Project with Chlorine Resistant Elastomers

When developing any product with a chlorine resistant elastomer, understanding the benefits and challenges is important to ensuring its success and meeting the demands of your industry. Working with Gulf, a team that has over 100 years combined experience, means that you will have insight into which chlorine resistant elastomer is best for your product, how to keep your costs down, which safety measures apply to your assembly, what compliance standards you need to meet, and solutions to any complex issue that comes up during the process. You are in good hands with Gulf. Contact our team for your next chlorine resistant elastomer project.

Check out a new blog about chlorine resistant elastomers and the top 10 questions we get as a chlorine resistant elastomer manufacturer.