Applications and Benefits of Convoluted Diaphragms in Industrial Solutions

Various Industrial application manufacturers have come to rely on diaphragms for efficiency and maximum performance. If your application needs airtight and fluid-tight seals, our rubber and plastic component experts may recommend a convoluted diaphragm to get the job done right.

What makes convoluted diaphragms so common in industrial applications? They are superior at sealing and designed to withstand high-pressure differentials, fluctuations in temperature, and application movement. They also work with precision and are flexible and durable. Let’s take a look at some of the most common convoluted diaphragm applications and benefits for industrial solutions below.

Convoluted Diaphragm Applications

It’s important to understand which applications can benefit from convoluted diaphragms and why. The following review of convoluted diaphragm applications will help you learn more about the diversity in use and may help you make the best decision for your next project.

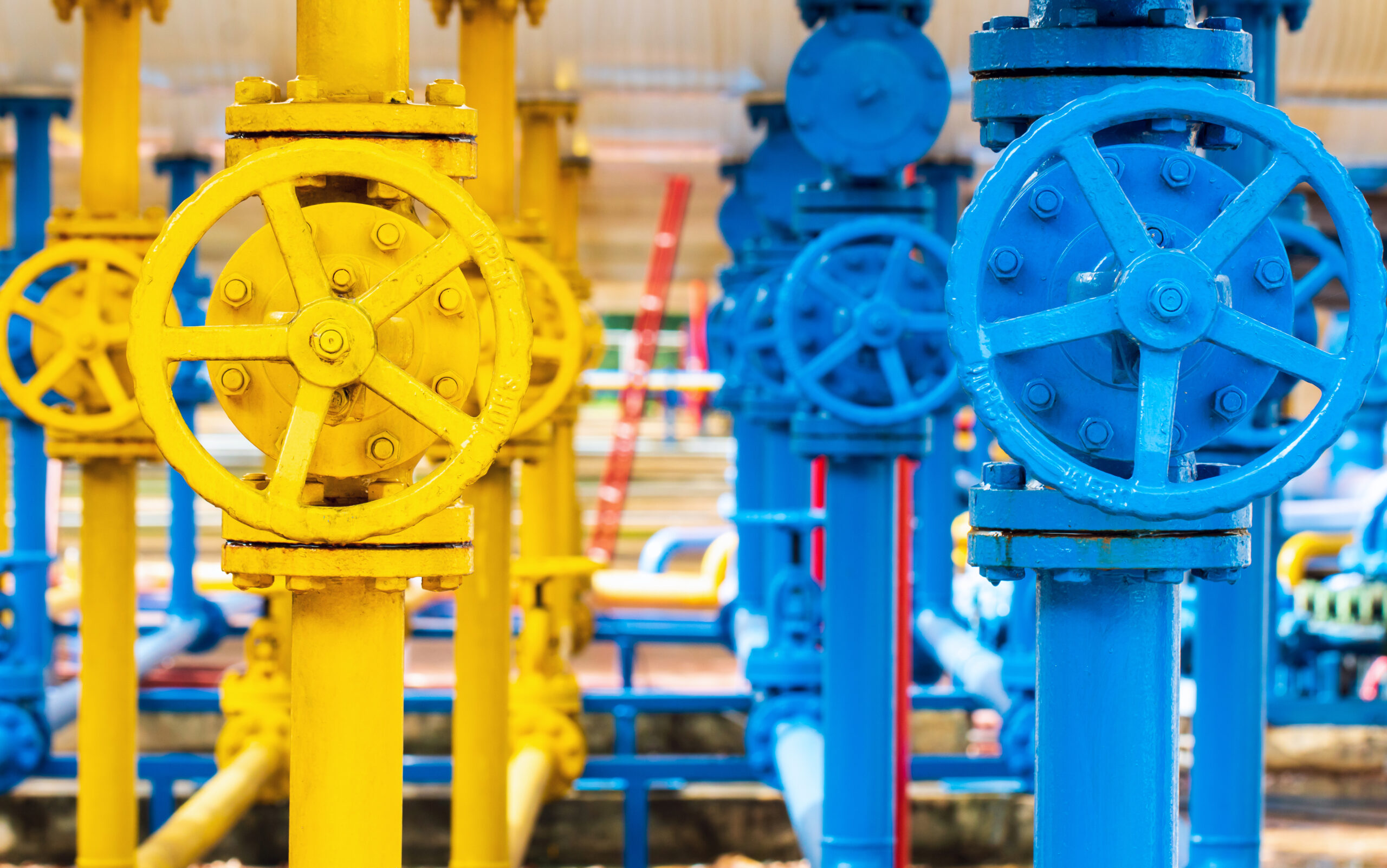

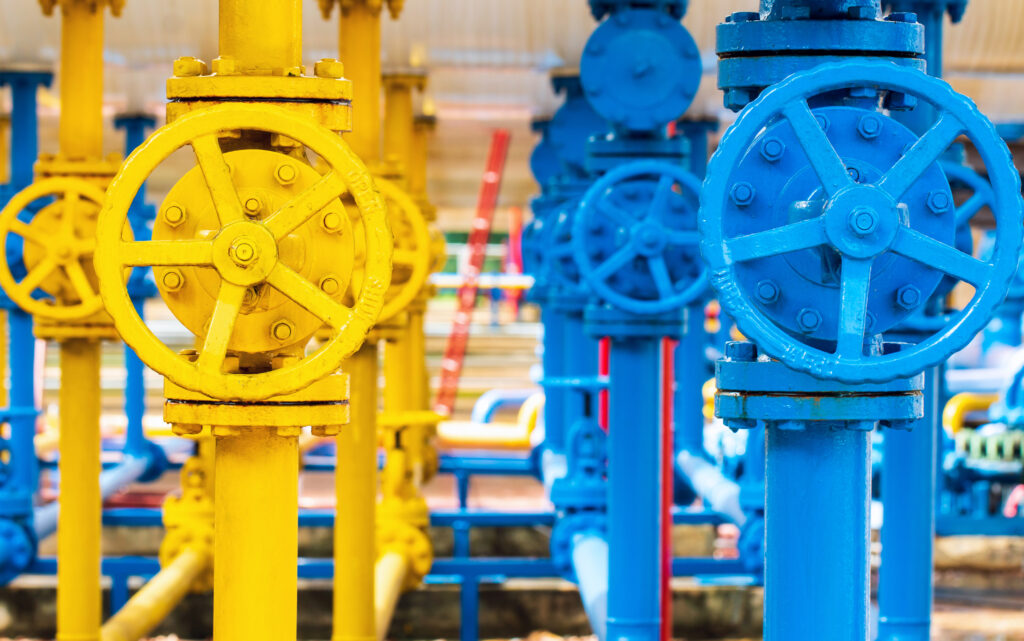

Pumps and Valves

One very common use for convoluted diaphragms are in pumps and valves. Here you’ll find the diaphragm offers precision flow control and pressure regulation. The flexibility of the diaphragm allows for a wide range of motion for gas or liquid without compromising the integrity of the seal. The consistent performance of this diaphragm makes it a great option when stable pressure and flow control are critical. The design of the convoluted diaphragm also accommodates higher deflection and stroke lengths, improving pump efficiency and response time. Lastly, the reduced stress on the diaphragm minimizes its wear and promotes a longer lifespan.

Actuators

Actuator systems require precise and dynamic motion control. Convoluted diaphragms are often found in pneumatic and hydraulic actuators where a responsive and durable diaphragm is needed to manage movement and force.

Additional benefits using convoluted diaphragms in actuators include their high sensitivity. This means they respond quickly to changes in pressure, which improves the actuators accuracy and efficiency. In actuators, we also see convoluted diaphragms allowing the application to deliver smooth and repeatable motion over long cycles and reduced material fatigue.

Pressure Regulators

Pressure regulators require consistent pressure levels for gas or liquid and convoluted diaphragms offer just that. Even in high-pressure or hard environments, these diaphragms provide a reliable and durable solution. Other key benefits of convoluted diaphragms in pressure regulators include high sensitivity, a long life span, and leak-free operations.

Industrial Sensors

The pressure or force in industrial sensors needs to be monitored, and the convoluted diaphragms play an important role as the sensing element. Their ability to flex under pressure changes makes them ideal for pressure transducers, gauges, and monitoring devices.

Versatility and consistency is another benefit of convoluted diaphragms in industrial sensors. They can withstand harsh environmental conditions including high-pressure, corrosive conditions, and extreme temperatures. They’re also very reliable, which means your industrial sensor will provide accurate readings.

Compressors

Compressors in industrial, HVAC, and automotive applications benefit from the flexibility and reliability of convoluted diaphragms. Their compression cycles require pressure regulation and effective sealing, and convoluted diaphragms work extremely well in these conditions. Efficiency is important in industrial systems, which is why the flexible design of the convoluted diaphragms works well allowing for smooth operation and minimal energy loss. Another benefit that is top of mind for compressor manufacturers is the ability to prevent cracks and deformation under high pressure giving the reduced material stress.

Medical Devices

Convoluted diaphragms are also a key component in medical equipment, such as ventilators, infusion pumps, and diagnostic devices. Their reliability and sensitivity are critical in ensuring patient safety and device accuracy.

Precision and sensitivity are always crucial when designing medical devices, and convoluted diaphragms provide consistent, responsive performance, every time. Made of medical-grade materials, these diaphragms are also sterile and safe, meeting strict medical industry standards. The long lifespan of convoluted diaphragms also works well for medical devices performance and longevity.

Partner with an Expert Convoluted Diaphragm Manufacturer

The engineers at Gulf U.S. Engineered Rubber and Plastics Solutions (Gulf) specialize in custom designing and manufacturing high-quality convoluted diaphragms. Each project is tailored to your industry specifications and application requirements. With decades of experience and expertise in rubber and plastic, we deliver solutions that ensure reliability, efficiency, and a long service life.

Give us a call today to talk about your next project. Together, we’ll discover if a convoluted diaphragm is the right component for you to enhance the performance of your systems or equipment.